Eating in space is tricky, but Texas A&M University and NASA have partnered for nearly 20 years to make sure astronauts have nutritional (and tasty) food while on their missions. Gone are the days of astronauts having to eat “cube and tube” foods. These days, food scientists are creating menus for astronauts that are flavorful, but practical for consumption in a space environment.

“About 30% of the food items the astronauts consume in space are made at our facility,” said Dr. Suresh Pillai, associate head of the Department of Food Science and Technology in the Texas A&M College of Agriculture and Life Sciences, who serves as principal investigator of the project and the facility director. “That means 50-60 of the food menu items in thermostabilized pouches that wind up in space come from here.”

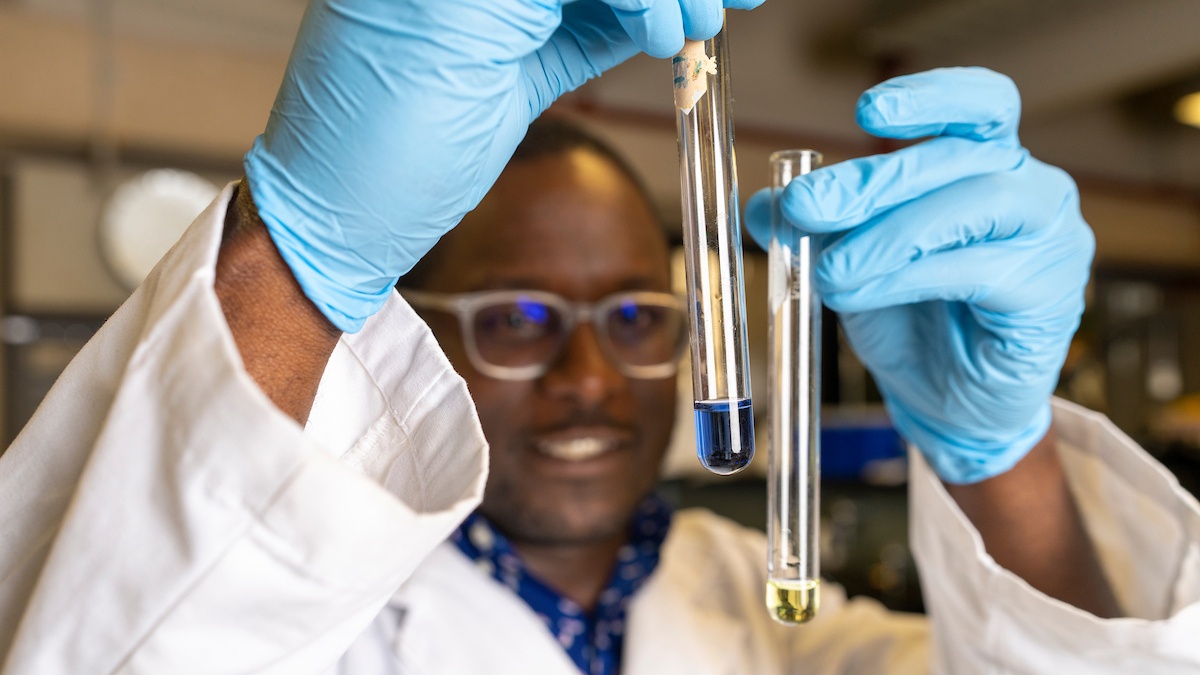

Researchers are constantly testing new foods and recipes to add to the menus, including gumbo, lasagna and chocolate pudding. The food is then prepared at the Space Food Research Facility on Texas A&M’s main campus and made ready for use.

“Astronauts make many sacrifices in their commitment to travel in space, so we feel they should have foods that are fun and flavorful while they are up there,” said John Vollmer, a food scientist and employee of Leidos, a NASA subcontractor.

Vollmer, who works from the Space Food Research Facility, said the mass of the food impacts the overall weight and payload of the flight. That makes it even more important that the astronauts enjoy their meals and eat everything they provide for them on their missions.

About 30% of the food items the astronauts consume in space are made at our Texas A&M facility.

Meals at the Space Food Research Facility are prepared by food scientists representing NASA and Texas A&M working together. The meals are made in a manner similar to Meals-Ready-to-Eat (MRE), used by the military, but are specially developed to meet the nutritional needs of astronauts in space.

Many of the ingredients for the foods prepared at the facility are purchased fresh from grocery stores in the Bryan-College Station area, where the university’s main campus is located. Ingredients are weighed, and their use in each recipe is verified. The prepared food is then placed in commercial pouches, and the top is sealed.

“The food processing techniques and packaging solutions vary based on the item’s perishability, ingredient composition and the amount of the item we have on inventory,” Vollmer said. “The food needs to be nutritionally balanced and, most of all, safe to eat.”

Since the items are stored without refrigeration, they have to be prepared, treated and packaged to last for months or even years.

Michael Miller/Texas A&M AgriLife

Pillai said the Space Food Research Facility is unique in that it provides government, industry and academic scientists the opportunity to investigate the combination of a variety of food processing technologies in addition to legacy thermostabilization of foods.

It also gives Texas A&M students majoring in food science or nutrition the unique opportunity to gain experience in a highly controlled setting where quality assurance is taught and followed, providing translatable skills in their careers upon graduation.

Because where else can you say you helped pack lunch for an astronaut, except at Texas A&M?